1. Requirements and International Standards for Fire-Resistant Elevator Insulation Doors

Fire results from a chemical reaction between combustible materials and oxygen, producing flames, heat, and smoke. Effective fire prevention must address all three of these elements. Globally, building components used in fire protection, such as fire doors, must be rigorously tested to meet specific requirements. These tests evaluate components based on insulation performance and structural integrity, typically by exposing them to controlled fire conditions in a furnace for a predetermined period.

Countries in Europe and North America have established comprehensive performance testing standards for elevator fire doors. Standards such as DIN 1363-1 and DIN EN 1364-1 address fire resistance testing for non-load-bearing building components, and EN 81-58:2003, published in 2004, specifically covers fire testing for elevator landing doors.

Domestic Standards in China:

– GB/T 27903-2011: Test Method for Integrity, Insulation, and Heat Flux of Elevator Landing Doors in Fire

– GB/T 24480-2009: Test Methods for Leakage, Insulation, and Radiation of Elevator Landing Doors in Fire

– GB50016-2015: Code for Fire Protection Design of Buildings

– GB 8624-2012: Classification for Burning Behavior of Building Materials and Products

– GB/T 20285-2006: Classification for the Smoke Toxicity Hazard of Materials

In China, the Code for Fire Protection Design of Buildings (GB50016-2015), issued by the Ministry of Public Security and the Ministry of Housing and Urban-Rural Development, came into effect on May 1, 2015. Article 6.2.9 of this code stipulates that “the fire resistance rating of elevator landing doors shall not be less than 1 hour and must meet the integrity and insulation requirements specified in the national standard ‘Test Method for Integrity, Insulation, and Heat Flux of Elevator Landing Doors in Fire’ (GB/T 27903).”

In early 2019, the Ministry of Housing and Urban-Rural Development issued a draft version of the General Code for Fire Protection in Buildings, which further emphasizes the importance of elevator fire protection. Article 6.4.2 states that the fire resistance rating for single-layer doors must be no less than 1 hour, reflecting the trend toward stricter fire safety regulations for elevator landing doors.

2. Advantages of Applying Microporous Boards in Elevator Floor Door Systems

Our company’s MIP-950 microporous board is an optimal solution for passive fire protection in elevator floor doors. Its use in fire-resistant insulation doors provides several key advantages, fully complying with international fire safety standards:

– Non-Flammability: The MIP-950 microporous board is non-combustible and contains no flammable components. In the event of a fire, it does not release harmful substances, making it an environmentally friendly and safe thermal insulation material. It poses no threat to human health or the environment.

– Exceptional Thermal Insulation: Thanks to its nanoporous structure and specialized additives, the board effectively minimizes heat transfer through convection, conduction, and radiation. Even at elevated temperatures, its thermal conductivity remains lower than that of static air, showcasing its superior insulating capabilities. Traditional insulation materials like silicate ceramic fibers and calcium silicate, on the other hand, experience a significant rise in thermal conductivity with increasing temperatures, resulting in diminished insulation performance .

– Lightweight and Thin Design: The MIP-950 microporous board provides the same thermal insulation performance as conventional materials at just 1/4 to 1/6 of their thickness. For instance, at a flame temperature of 1160°C, a 25mm-thick board can maintain a cold-side surface temperature of 128°C and a heat flux of 1643W/m², far below the national standard of 140°C and a heat flux limit of <15000W/m². This allows the thickness of fire-resistant elevator doors to match that of standard doors, offering considerable design flexibility. By contrast, achieving a 140°C cold surface temperature with ceramic fiber would require over 100mm of material thickness.

– Structural Integrity: MIP-950 has ample strength and is wrapped in a non-flammable glass fiber cloth, ensuring cleanliness and preventing dust release. The material maintains its integrity during normal elevator operations. In the event of a severe fire, the glass fiber coating may become brittle, shrink, or even melt, but the core material retains its structural integrity and insulating properties, ensuring reliable performance under extreme conditions.

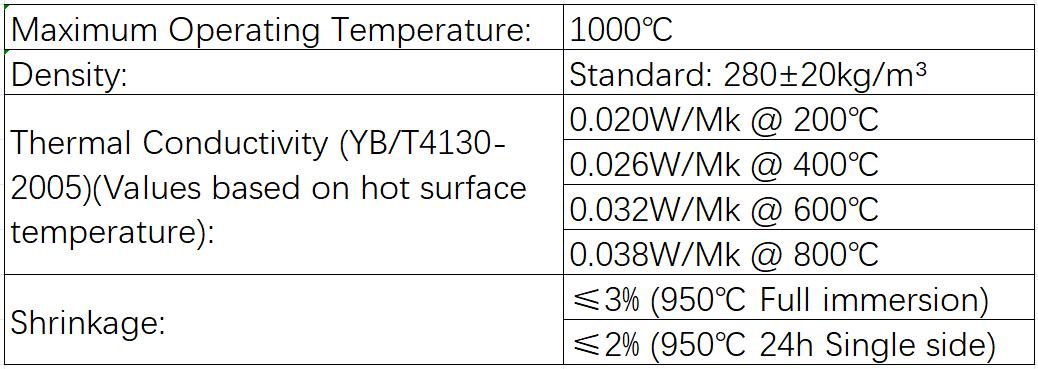

3. Performance Parameters

4. Typical Applications

Currently, there are no unified standards for the use of nanoporous insulation materials in elevator floor doors. The design process should consider various factors, such as the required fire resistance duration, the presence of reinforcements, and specific component details. Any weak points identified during flame testing should be reinforced to ensure greater protection.

Based on customer experiences:

– To meet the EI-120 standard (120 minutes of integrity and thermal insulation), microporous boards with a thickness of 22-25mm are recommended.

– For the EI-60 standard (60 minutes of integrity and thermal insulation), microporous boards with a thickness of 16mm or above are advisable.

Optimizing Fire-Resistant Insulation:

In general, using larger insulation boards provides better thermal protection, as it reduces the likelihood of heat transferring through gaps to the back. Insulation boards with an area matching the surface of the door deliver the most effective insulation. However, these boards must be installed above the door reinforcements, which may affect door thickness reduction.

Another design approach avoids placing insulation boards on reinforcements. While heat may transfer through the reinforcements, this design can still pass fire tests as temperature probes are typically not placed at reinforcement positions, allowing for thinner door profiles.

Processing Dimensions for Microporous Boards:

– Length: ≤2800mm

– Width: ≤750mm

– Thickness: ≤50mm

Other Product Characteristics:

– Core Material: Gray nanoporous insulation material

– Coating: White glass fiber cloth (hydrophobic treatment available upon request)

Application Limitations:

Due to the inherent strength limitations of nanoporous materials, it is advised to avoid designing insulation components that are excessively long and thin. For extended insulation areas, it is recommended to divide the components into several sections for assembly. For tailored solutions, please consult our sales team for guidance.

Stay Connected

For live updates and behind-the-scenes content, follow us on:

- LinkedIn: Firebird LinkedIn

- YouTube: Firebird YouTube

- Facebook: Firebird Facebook

- Website: Firebird main website