1. Application Examples of Microporous Boards in the Aluminum Industry

1.1 Application in Aluminum Melting Furnaces

In the aluminum industry, aluminum melting furnaces are a crucial part of the production process. These furnaces need to maintain optimal temperature distribution to ensure uniform liquid metal, which in turn guarantees the quality of the final product for customers. The refractory insulation system is extremely important for ensuring proper temperature control in aluminum melting furnaces.

MIP-950 or MIP-800 flexible panels are ideal for use in aluminum melting furnaces. They help reduce heat loss, enhance product quality, and lower operating costs. MIP-800 is fully covered with aluminum foil to prevent degradation from moisture absorption during the casting process, and it can be bonded to the furnace lining using high-temperature adhesives. Compared to traditional insulation materials like glass wool, mineral wool, and ceramic fibers, microporous insulation boards offer significant space and energy savings.

Advantages:

– Thickness can be reduced by at least 50% compared to ceramic fiberboard, resulting in a 9°C temperature drop.

– Reduces heat loss by 30% and decreases the cold surface temperature by 15°C compared to ceramic fiberboard of the same thickness.

– Lower heat loss improves product quality and extends furnace service life.

– MIP-950 or MIP-800 products can be cut and installed on-site using standard tools and techniques.

1.2 Application in Aluminum Transfer Ladles

In the aluminum processing industry, high production flexibility and reduced costs are essential. Aluminum transfer ladles are widely used to transport molten aluminum between facilities, enabling efficient road transport of molten metal. With the current trend in China, aluminum casting plants are increasingly located near electrolytic aluminum plants, allowing for direct processing of molten aluminum without the energy-intensive process of cooling and re-melting ingots.

The temperature of molten aluminum typically reaches around 750°C.

MIP-800 Solution

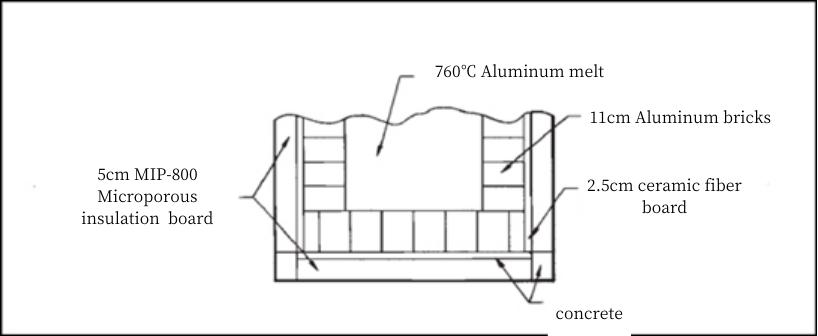

The lining system for aluminum transfer ladles, as illustrated in Figure 4, includes:

– Package shell

– 5 cm MIP-800 microporous boards

– 2.5 cm ceramic fiberboard

– 11 cm high-alumina brick

– Aluminum melt

The panel thickness depends on the ladle’s configuration and size. MIP-800 is covered with aluminum foil to protect against moisture absorption from casting materials, and it can be adhered to the lining with high-temperature adhesives.

Advantages:

– A 5 cm MIP-800 panel provides heat loss equivalent to an 18 cm mineral wool panel.

– Increases ladle capacity while reducing operating costs.

– Maintains the existing furnace shape, reduces heat loss, and conserves energy.

– MIP-800 can be easily cut and installed on-site.

This version maintains clarity while emphasizing the benefits of MIP-950 and MIP-800 in aluminum melting furnaces and transfer ladles.

1.3 Application in Aluminum Launders

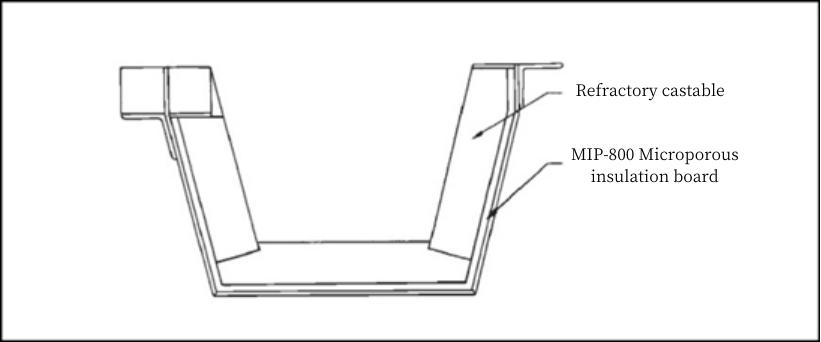

To transfer molten aluminum from the melter to the casting facilities, aluminum processors use launder systems to distribute the molten metal and remove bubbles, thus enhancing processing quality. To prevent the “freezing” of molten aluminum and ensure consistent flow, an effective insulation system is required to maintain the melt temperature, typically around 750°C. Proper insulation also helps minimize heat loss, reducing the need for excessive reheating of the aluminum melt.

MIP-800 is ideal for this application. The thickness of the insulation depends on the specific configuration and size of the launder. MIP-800 is fully covered with aluminum foil to protect against moisture absorption from casting materials, and it can be bonded to the launder lining with high-temperature adhesives.

Advantages:

– Compared to silicon carbide board, MIP-800 provides better thermal efficiency and a longer service life.

– The use of MIP-800 minimizes heat loss in the launder system, reducing the need for reheating and improving overall energy efficiency.

– MIP-800 can be cut and installed on-site using standard tools, making the installation process efficient and straightforward.

1.4 Application in Electrolyzers

In the new cathode structure electrolyzers, the tank voltage typically ranges between 3.70-3.75V, which is about 0.3V lower than conventional electrolyzers. This voltage reduction translates to a roughly 13% decrease in the electrical energy input for resistance heating. To maintain thermal balance for normal production at standard electrolysis temperatures, the heat dissipated from the system must also be reduced by about 13%. Therefore, insulating the electrolyzer—especially the new types—is crucial for reducing energy consumption and maintaining process thermal balance.

Figure 7: Electrolytic aluminum electrolysis cell using MIP-950 microporous board

Due to the structural constraints of electrolyzers, the space for installing insulation is limited: 10-12mm on the side walls and about 15mm on the end parts. The required thermal insulation temperature is 950-960°C. These dimensions and conditions make microporous insulation materials, like MIP-950, an ideal choice. After implementing MIP-950, noticeable improvements have been observed, including reduced power consumption, higher current density, and stable voltage application.

However, due to the complex structure and operating conditions of electrolytic cells, a comprehensive design and calculation are necessary to determine an optimal insulation plan. In general, the insulation should be moderate at the bottom of the tank. The sides of the electrolyzer should not be over-insulated, but extra insulation is needed under the cathode steel rods at the bottom of the tank and at the four corners of the electrolyzer to enhance thermal performance.

Stay Connected

For live updates and behind-the-scenes content, follow us on:

- LinkedIn: Firebird LinkedIn

- YouTube: Firebird YouTube

- Facebook: Firebird Facebook

- Website: Firebird main website