1.1 Microporous Board in Glass Melting Furnaces

Effective insulation of key furnace components, including the crown, breast walls, tank walls, tank bottom, regenerators, and more, is essential for enhancing thermal efficiency. Proper furnace insulation greatly reduces heat loss from the structure, improves working conditions for operators, and increases the furnace’s thermal capacity, leading to more stable and higher molten glass temperatures. This results in better temperature distribution and flow within the furnace, improving both glass quality and production rates while reducing fuel usage.

Benefits of Furnace Insulation:

- Energy Efficiency: Insulation reduces heat loss dramatically, for example, by 72% at the tank bottom, 87% at the tank walls, 79% at the breast walls, 80% at the regenerators, and 49% at the crown.

- Increased Melting Rate: Melting rates can rise by 15% to 20% with the same energy input, with average molten glass temperatures increasing by 30–40°C, enhancing glass clarity and homogenization for better quality and yield.

- Extended Lifespan and Safety: Lower thermal loads on the furnace crown prolong its lifespan and improve operational safety.

Microporous boards are particularly beneficial in the furnace crown due to their low thermal shrinkage and high insulating efficiency. They help prevent fire propagation through insulation seams, which otherwise accelerates wear in the insulating layers and leads to greater heat loss. Additionally, the reduced weight of microporous board minimizes the risk of overloading the furnace crown.

In the forehearth, where molten glass is conditioned, insulating the cold face reduces weight and energy loss, decreases the temperature gradient of the glass, and lowers the surface temperature, ensuring greater safety for personnel.

Reducing heat loss is especially critical in air preheater systems, where the goal is to supply air heated to 750°C to the furnace. The combination of microporous boards and pipe insulation reduces the temperature difference between the heat exchange chamber and the furnace to less than 30°C. The thin, lightweight profile of microporous board is particularly useful in the confined spaces of heat exchangers, where structural support and space limitations are important factors.

Typical melting furnace temperatures exceed 1550°C, while batch temperatures fluctuate around 1100°C. The energy demands of this process are substantial, making heat loss control vital for maintaining product quality. For example, in a glass melting process at 1300°C, applying a 22mm layer of microporous insulation lowered surface temperatures from 159°C to 114°C and bottom temperatures from 184°C to 130°C, reducing overall heat loss by 45%.

In large furnaces capable of holding up to 2,000 tons of molten glass, the compressible insulation layer at the bottom plays a crucial role in heat retention. Microporous boards exhibit excellent load-bearing capabilities, showing only minimal compression under loads of 100 kN/m², with a mere 5% compression rate. Since their thermal conductivity remains stable across a wide density range, they provide consistent insulation performance even under mechanical loads.

By combining advanced float glass furnace technology with precise insulation-based temperature control, it’s possible to produce flat glass in thicknesses ranging from as thin as 0.3mm to as thick as 25mm. Controlling heat loss throughout glass production enhances energy efficiency while reducing the industry’s environmental footprint.

1.2 Application in Automotive Glass Hot Bending Process

Automotive glass is frequently manufactured using the gravity bending and tempering technique. In this method, pre-processed flat glass is placed horizontally on a mold ring and transferred into a heating furnace. Once the glass reaches its softening point (around 650°C), it is lifted by a vacuum suction cup, released to fall freely, and shaped by gravity to fit the mold ring. The glass is then quickly moved to a cooling zone for rapid quenching and tempering before being sent to the unloading area. This entire procedure is managed by pre-set parameters, including heating zone temperatures, heating duration, cooling air pressure, cooling time, and transport speed.

Precise control over production parameters, especially heat, is crucial. Traditional insulation materials like silicate fiber and mineral wool often suffer cumulative damage at temperatures exceeding 400°C, leading to partial collapse of the insulation layer and a decline in thermal performance.

Microporous boards offer the benefit of stable thermal performance during long operating cycles at high temperatures, with much lower thermal conductivity than traditional insulation materials. After a decade of continuous use (with glass fiber cloth wrapping), the only noticeable deterioration is slight weakening of the E-grade glass cloth on the surface, while the microporous board remains intact. This stability is highly advantageous for maintaining continuous production line operations.

1.3 Innovations in Insulation Methods During Production

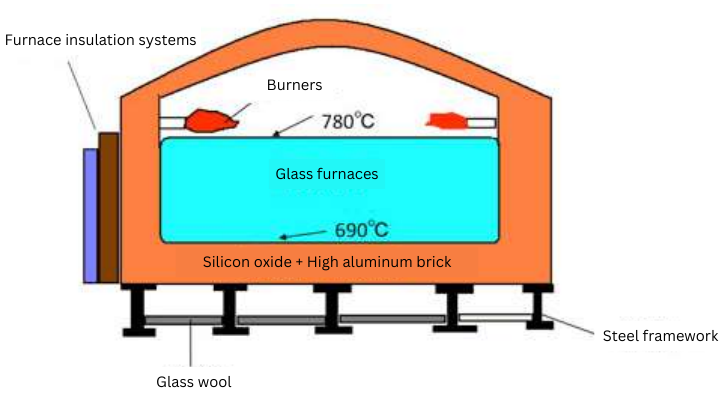

In one instance, a client needed to produce both clear and colored glass in the same furnace, requiring an increase in bottom temperature from 690°C to 730°C. The solution was to replace part of the glass wool insulation with microporous boards, allowing the bottom material temperature to reach 730°C. The installation and removal of support boards, as depicted, allow for fast and easy temperature adjustments.

Replacing the existing fiberglass insulation with microporous boards can potentially raise the bottom material temperature from 690°C to 730°C. As shown in Figure 7, this method allows for quick and easy adjustments to heat and temperature through the installation and removal of support boards.

1.4 Important Considerations

Microporous boards are primarily composed of amorphous silica, which has a lower heat resistance than refractory bricks or advanced ceramic fibers. The long-term operating temperature for MIP-1000 materials is 1000°C, while for MIP-800 materials, it is 800°C. Exceeding these limits may result in increased shrinkage, leading to safety concerns. Therefore, when determining the thickness of refractory and insulation layers, it’s important to calculate the temperature distribution based on each layer’s thermal conductivity, ensuring the microporous insulation stays within its safe operating range. Adjustments to the refractory structure and thickness may be required.

2. Conclusion

Careful management of heat loss throughout the glass production process is critical for optimizing energy efficiency and reducing environmental impact. The use of microporous insulation systems offers several key benefits:

- Lowest Thermal Conductivity: Enables precise control over glass temperature.

- Thin and Lightweight: Provides the most space-efficient insulation solution.

- Fiber-Free: Safe for the environment and human health.

- Long-Lasting Performance: Stable operation between 800°C-1000°C, with minimal shrinkage even at peak temperatures, and excellent recyclability.

- Versatile: Can be integrated with prefabricated products for a wide range of applications.

- Easy to Handle: Simple to cut and install.

- Space-Saving: Available in various formats for confined spaces.

- Multiple Insulation Options: Suitable for high-temperature and critical heat loss scenarios.

The increasing adoption of microporous boards in the glass industry highlights their effectiveness in cutting energy use and emissions. Though initial investment costs may be higher than those for traditional materials, the energy savings realized over time justify the expense. As the need for energy efficiency and emission reductions continues to rise, the use of microporous board in the glass sector is expected to grow steadily.

Stay Connected

For live updates and behind-the-scenes content, follow us on:

- LinkedIn: Firebird LinkedIn

- YouTube: Firebird YouTube

- Facebook: Firebird Facebook

- Website: Firebird main website