Exhibition Name: Glass – We Are GLASS

Exhibition Overview:

At Glasstec, the world’s foremost trade fair for the global glass industry, top innovations and trends in glass manufacturing converge under key themes such as decarbonization, the circular economy, and digital transformation. From glass production advancements to high-performance finishing technologies, innovative new products, and cutting-edge applications, Glasstec leads the industry. This event highlights how the international glass community tackles sustainability challenges and adapts to digital evolution, offering valuable insights that will give your business a competitive edge.

Exhibition Dates: October 22–25, 2024

Venue: Messe Düsseldorf, Germany

Booth Location: Hall 12, Stand 12F28

Booth Highlights:

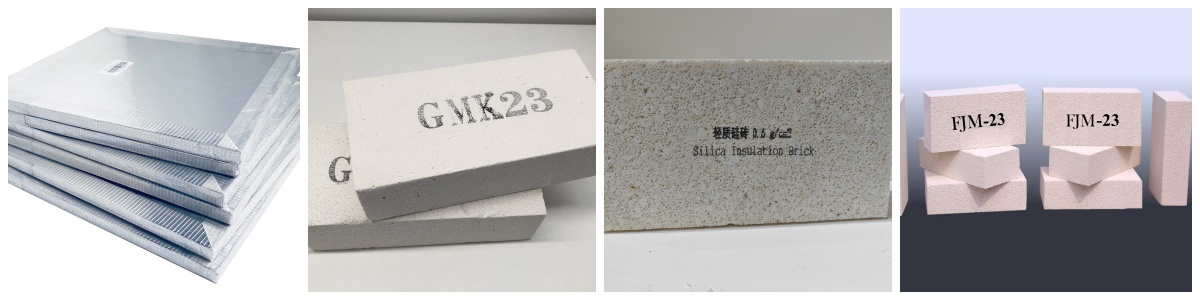

1. Microporous Insulation Board: Offering insulation performance up to four times better than conventional materials, this board is designed for temperatures between 500℃ and 1200℃, positioning it as one of the most effective insulating solutions available.

2. GMK23 Anorthite Insulating Firebrick: At Glasstec 2024, Firebird will proudly present the GMK23 Anorthite Insulating Firebrick, matching the quality of top-grade 23 insulating bricks. Produced using a slurry foaming casting method, GMK23 offers superior thermal efficiency, low thermal conductivity, and high resistance to thermal shock—ideal for hot face lining and backup insulation across various industries.

3. Silica Insulation Brick: Crafted from top-grade minerals and sintered without hazardous fillers, these bricks are optimized for glass melting furnaces and hot blast stoves, reducing both NOx and CO2 emissions.

4. FJM Series Insulating Firebrick: Engineered with a controlled pore structure, these versatile firebricks are perfect for hot face refractory linings and backup insulation applications in numerous industries.

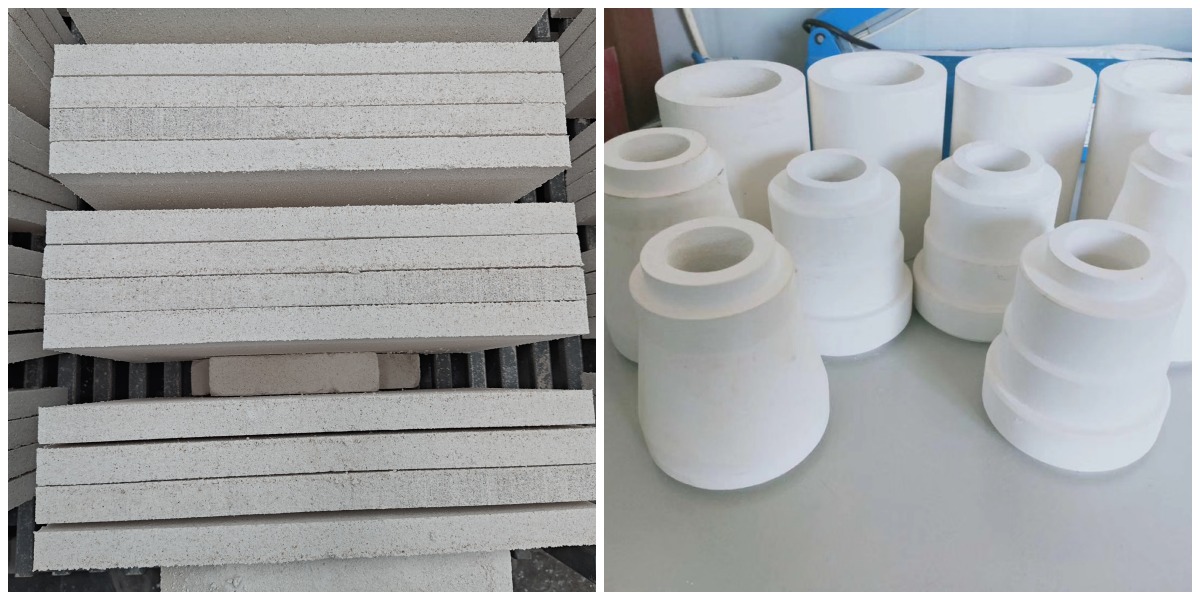

5. Glass Furnace Bottom Brick: Firebird provides a range of dense and insulating blocks for glass furnace bottoms and sidewalls, meticulously designed to ensure long-lasting performance, durability, and cost efficiency in glass furnace applications.

6. Bubble Alumina Brick: With high purity bubble alumina as its main component, this low-density, insulating refractory is formed by vibration pressing and sintered at temperatures above 1700°C, making it exceptionally rigid and durable.

7. CASI Nano Insulation Brick: Designed to replace traditional calcium silicate and ceramic fiber boards, CASI Nano Insulation Brick combines the strength of insulation bricks with the low thermal conductivity of ceramic fibers. Made from Al2O3, SiO2, and CaO, this brick is manufactured on a fully automated production line.

8. High Density Calcium Silicate Board: Reinforced with glass or carbon fiber, Firebird’s high-density calcium silicate board withstands temperatures up to 1000℃. Ideal for high-tensile and torsional strength applications, it resists wetting by liquid non-ferrous metals, making it suitable for casting environments. CNC precision machining is available for tight tolerances.

Why Visit Firebird’s Booth?

At Stand 12F28 in Hall 12, Firebird’s expert team will showcase these advanced refractory products and discuss ways they can optimize glass manufacturing processes. From energy savings to efficiency gains, Firebird has solutions tailored to meet the unique needs of the glass industry.

Stay Connected

For live updates and behind-the-scenes content, follow us on:

- LinkedIn: Firebird LinkedIn

- YouTube: Firebird YouTube

- Facebook: Firebird Facebook

- Website: Firebird main website