Introduction

The cement industry, as a high energy consuming sector, faces significant pressure to reduce energy consumption and emissions. With increasing national requirements for environmental protection and energy efficiency, cement companies urgently need to achieve energy savings through technological innovation and material upgrades. Zhengzhou Fanbo New Materials Co., Ltd., a professional supplier of microporous insulation materials, is committed to providing efficient and energy-saving insulation solutions for the cement industry, helping enterprises achieve green and sustainable development.

I. Advantages of Microporous Board

1. Excellent Thermal Insulation Performance

Microporous board minimizes solid conduction, convection, and thermal radiation, achieving superior insulation performance. Its thermal conductivity is as low as 0.020-0.038 W/m·K, far exceeding traditional insulation materials, making it particularly suitable for applications with strict space and weight requirements.

2. Lightweight and High Strength

The density of microporous board is only 200-300 kg/m³, with a strength of up to 0.7 MPa, reducing equipment load while ensuring material durability.

3. High-Temperature Resistance

Microporous board can withstand temperatures above 800°C, with a thermal shrinkage rate of less than 0.5%, ensuring long-term stable performance in high-temperature environments.

4. Environmental and Energy-Saving Benefits

By reducing heat loss, microporous board significantly lowers energy consumption, helping cement companies achieve energy-saving and emission reduction goals.

II. Insulation Needs in the Cement Industry

1. Energy-Saving and Emission Reduction Needs

In cement production, surface heat loss from the firing system accounts for about 8% of total heat consumption, indicating significant energy-saving potential. The use of microporous board can effectively reduce surface temperatures and minimize heat loss.

2. Equipment Stability Needs

Excessive temperatures in the grinding system can cause the tube mill to automatically shut down, affecting production efficiency. Microporous board effectively controls slide shoe temperatures, ensuring stable equipment operation.

3. Process Optimization Needs

In flue gas dust removal and waste heat utilization systems, scientific insulation measures can improve dust removal efficiency and waste heat utilization, further optimizing production processes.

III. Applications of Microporous Board in the Cement Industry

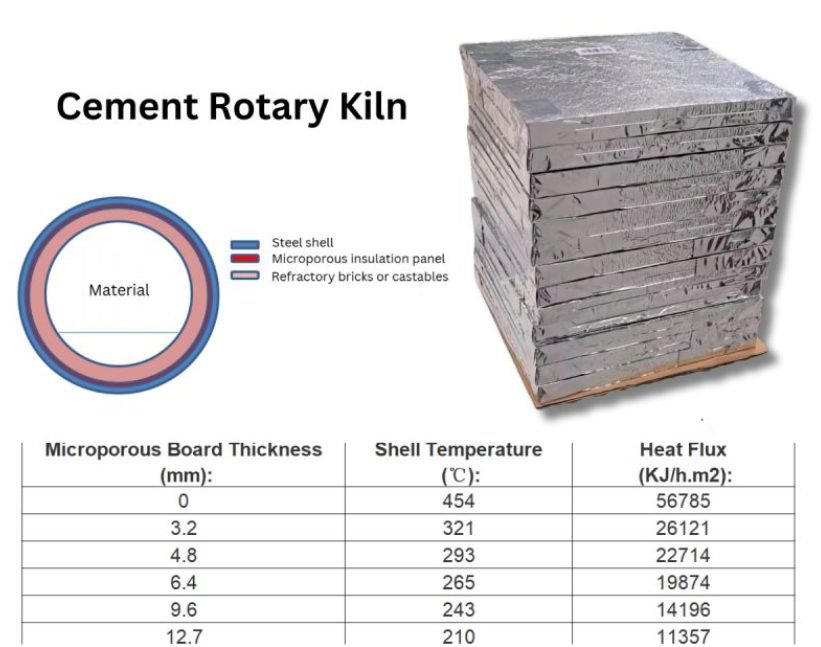

1. Firing System

- Application Areas: Cyclones, rotary kilns, kiln hoods, tertiary air ducts, etc.

- Effects:

- Compared to traditional insulation materials, the same thickness reduces surface temperatures by 20~30°C and heat loss by over 30%.

- Case Study: Using 114mm refractory brick + 80mm microporous board, the surface temperature dropped from 221°C to 90°C, a reduction of 131°C.

2. Grinding System

- Application Areas: Tube mill slide shoes.

- Effects:

- Only 5mm of microporous insulation felt is needed to effectively control slide shoe temperatures, preventing equipment shutdowns and improving operational efficiency.

3. Flue Gas Dust Removal and Waste Heat Utilization Systems

- Application Areas: Dust collectors, waste heat boilers, etc.

- Effects:

- Optimized insulation measures improve dust removal efficiency and waste heat utilization, reducing energy consumption.

IV. Advantages of Zhengzhou Firebird New Materials

1. Professional Technical Team

Zhengzhou Fanbo New Materials Co., Ltd. has long been dedicated to the research, production, and technical services of microporous insulation materials, boasting advanced domestic production facilities and a comprehensive service system.

2. Diverse Product Selection

We offer a variety of microporous insulation materials, including:

- Silica Microporous Board: Thermal conductivity as low as 0.020-0.038 W/m·K, suitable for high-temperature environments.

- High-Quality Micron Board: Cost-effective, suitable for medium and low-temperature environments.

- Economical Micron Board: Significant cost benefits, ideal for large-scale applications.

3. Customized Solutions

We provide space-saving, lightweight, and energy-efficient solutions tailored to the equipment configuration and operating conditions of cement companies, helping them achieve energy-saving goals.

4. Success Stories

- Case 1: In a cement kiln preheater system, using 114mm refractory brick + 80mm microporous board reduced surface temperatures by 49°C compared to traditional solutions.

- Case 2: Using 15mm microporous board in the transition zone of a rotary kiln reduced surface temperatures by 70~110°C and heat loss by 50%.

V. Future Outlook

The cement industry still has immense potential for energy savings. Zhengzhou Fanbo New Materials Co., Ltd. is willing to collaborate with customers to achieve energy efficiency, improve equipment stability, and optimize production processes through high-performance microporous insulation materials, contributing to green and sustainable development.

Conclusion

Microporous board, with its exceptional performance and wide range of applications, is becoming a crucial choice for energy-saving and emission reduction in the cement industry. Zhengzhou Fanbo New Materials Co., Ltd. will continue to provide high-quality products and services, supporting the cement industry in moving toward a greener and more efficient future.

Contact Us: For more information about microporous insulation materials, please visit our website or contact our professional team.

- LinkedIn: Firebird LinkedIn

- YouTube: Firebird YouTube

- Facebook: Firebird Facebook

- Website: Firebird main website