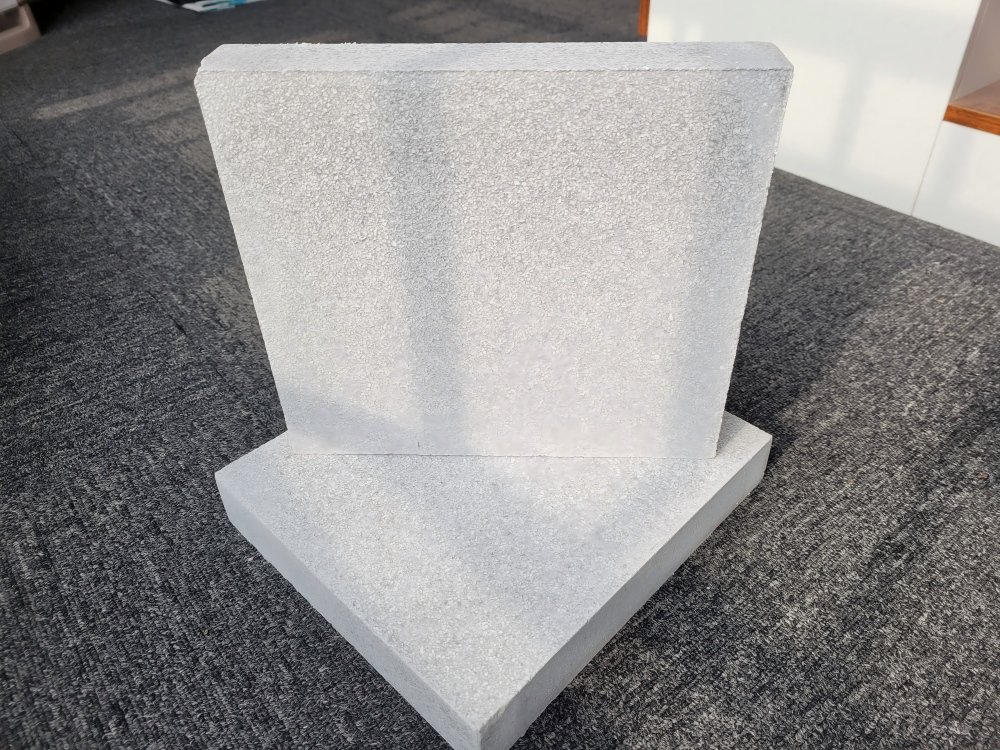

MIP-E Series Economy Microporous Board

Firebird MIP-E Series Microporous Boards are engineered to deliver high insulation performance at a more economical cost, making them a reliable choice for aluminum furnaces, cement kilns, and other high-temperature industrial systems.

- Ultra-Low Thermal Conductivity

- Stable Performance up to 1000–1200°C

- High Compressive Strength

- Cost-Effective Insulation Solution

- Excellent Durability with resistance to crystallization and powdering

What is MIP-E Series Microporous Board?

MIP-E Series Microporous Board is manufactured using carefully selected inorganic nano-scale refractory powders and formed by a proprietary fully-automated dry pressing process. This results in a board with a nano-scale microporous structure that effectively blocks all three modes of heat transfer: conduction, convection, and radiation. While maintaining the ultra-low thermal conductivity characteristic of traditional microporous insulation, the MIP-E series offers enhanced cost-efficiency — providing a new solution for industrial furnaces that require both thermal performance and budget optimization.

Firebird MIP-E Series Economy Microporous Board has been widely applied in China’s cement and aluminum industries. Its excellent energy-saving performance and cost-effectiveness have delivered proven value to our customers. Now, Firebird is introducing this series to the global market — providing industrial kiln users with a reliable and economical alternative for thermal insulation.

Zhengzhou Firebird New Material Co., Ltd

Product Grades of MIP-E Series Microporous Board

E1000A – Economy Grade (1000°C)

Reliable insulation with twice the performance of ceramic fiber and calcium silicate. Best for standard aluminum and cement applications needing stable, cost-effective insulation.

E1000B – Enhanced Grade (1000°C)

Upgraded formula with lower thermal conductivity and better heat-loss control than E1000A. Ideal for projects targeting improved energy efficiency.

E1200 – High-Temperature Grade (1200°C)

Advanced nano-composite structure with superior thermal performance at elevated temperatures. Designed for demanding aluminum, cement, steel, and glass furnace zones.

Applications of MIP-E Series Microporous Board

Firebird MIP-E Series Microporous Boards are designed for a wide range of high temperature insulation systems where energy efficiency and heat-loss reduction are essential. Their nano-porous structure and consistent thermal performance make them suitable for:

Aluminum Industry: Electrolysis cells, melting and holding furnaces, anode baking furnaces

Cement Industry: Preheaters, calciners, kiln hoods, tertiary air ducts, grate coolers

Ceramics: Roller kilns, tunnel kilns, shuttle kilns

Iron & Steel: Coke ovens, blast furnaces, reheating furnaces, hot blast stoves

Glass Furnaces: Melters, regenerators, annealing lehrs

General Industrial Furnaces: Heat-treating furnaces, carburizing furnaces, reactors, reformers

Key Features of MIP-E Series Microporous Board

Ultra-Low Thermal Conductivity

Nano-scale microporous structure effectively blocks conduction, convection, and radiation, delivering insulation performance far superior to ceramic fiber and calcium silicate.Stable High-Temperature Performance

Grades up to 1000–1200°C with excellent resistance to crystallization, powdering, and shrinkage, ensuring long-term reliability.High Strength & Easy Processing

Strong compressive strength with clean edges and easy cutting, allowing precise installation even in complex furnace areas.Energy-Saving & Cost-Efficient

Proven to reduce heat loss and fuel consumption in aluminum and cement industries, providing a balanced solution between performance and budget.Consistent Quality

Manufactured through a fully automated dry-pressing process, ensuring uniform density, tight joint fit, and stable performance across all grades.

What makes microporous board thermal conductivity lower than still air?

Microporous boards are engineered with a unique nanoporous structure that, combined with specific additives, significantly minimizes heat transfer through conduction, convection, and radiation across diverse temperature ranges. This high-performance insulation surpasses traditional materials like mineral wool, perlite, calcium silicate, ceramic fibers, and even advanced options like aerogel felts. Remarkably, the thermal conductivity of microporous board often falls below that of static air at most operating temperatures.

Advantages of Microporous Board:

- Nanoscopic Structure: Small particle size reduces contact, lowering heat conduction.

- Nanoporous Composition: Tiny pores (around 20nm) trap gases, nearly eliminating internal convection.

- Anti-Infrared Properties: Specialized powders block infrared radiation, further limiting heat transfer in high-temperature settings.

These characteristics make microporous materials ideal for industrial applications, offering exceptional thermal insulation and reliability in extreme environments.

Multiple Surface Covering Choices

Depending on factors like product type, operating temperature, handling requirements, and environmental conditions, microporous boards are available with various standard covering materials. These include:

– Aluminum Foil Covering

– Aluminum Foil Cloth Covering

– POF (Polyolefin) Film Covering

– Non-woven Fabric Covering

– Fiberglass Cloth Covering

Each covering material is chosen to suit specific application needs, ensuring optimal performance and durability in diverse industrial and operational settings.

- Technical Parameters

- Photo Gallery

| Item | E1000A | E1000B | E1200 | |

|---|---|---|---|---|

| Color | Grey | Grey | White | |

| Classification Temperature | °C | 1000 | 1000 | 1200 |

| Nominal Density | kg/m³ | 600±50 | 500±30 | 750±50 |

| Compressive Strength (10% deformation) | MPa | ≥0.7 | ≥0.7 | ≥0.7 |

| Shrinkage (Full Soak) | % | <1.5% (950°C × 3h) | -1.5% ~ 0.5% (950°C × 12h) | ≤2% (1100°C × 3h) |

| Shrinkage (One Side) | % | ≤0.5% (950°C × 3h) | ≤0.5% (950°C × 12h) | ≤0.5% (1100°C × 3h) |

| SiO₂ | % | >85 | >85 | — |

| SiO₂ + ZrO₂ | % | — | — | >88 |

| Others | % | <15 | <15 | <12 |

| Thermal Conductivity (W/m·K) | 400°C | 0.048 | 0.045 | 0.050 |

| 600°C | 0.060 | 0.055 | 0.065 | |

| 800°C | 0.070 | 0.065 | 0.075 | |

| Standard Sizes | L × W (mm): 200×180, 200×250, 230×160, 300×300 Thickness (mm): 25–80 (including 25, 30, 35, 40, 45, 50, 55, 60, 65, 70, 75, 80) Custom sizes available. | |||

| Surface Coating | POF film-covered | |||

Related Products

Why Choose Firebird?

At Firebird, we focus on one thing: delivering reliable refractory materials to our customers. To learn more about our refractory products, please visit our main website.

We have built a network of trusted manufacturers, and we use our experience to ensure that the products you receive meet your standards, every time. Our goal is to ensure you get the right materials at the right time, without complications.

Absolutely! We welcome plant audits and visits to our facilities. Please note that Firebird insulation refractory and high-performance refractories are manufactured in separate plants. Let us know your requirements, and we can arrange a convenient schedule for your visit to ensure a smooth and informative experience.

Yes, we provide free samples for testing purposes. However, customers are responsible for covering the courier charges associated with shipping the samples.

Our standard delivery time is generally between 10 to 15 days for most products. However, for specialized or customized bricks, the delivery time may extend to approximately one month. We strive to meet our customers’ timelines and will provide an estimated delivery date upon order confirmation.

We focus on transparency and quality at every step. After your order is placed, we:

- Share a detailed production plan.

- Provide weekly progress updates.

- Deliver a comprehensive test report for each batch.

- Carefully inspect the appearance, size, and weight of every product.

- Send shipment photos to keep you informed throughout the process.

This ensures complete visibility and trust in our manufacturing process.

We accept payments via T/T (Telegraphic Transfer) in major currencies such as Euro (EUR) and US Dollar (USD). Our payment terms are flexible, and we can accommodate different payment schedules based on the agreement.