1. Challenges

As materials continuously tumble inside the kiln, the refractory bricks must be dense enough to resist prolonged mechanical abrasion. However, this high-density material presents two issues:

1. High Thermal Conductivity: Over time, dense refractory materials wear down, leading to an increase in kiln shell temperature. This raises energy consumption, particularly with rising fuel costs, and can negatively affect the safety of mechanical components and nearby personnel.

2. Thermal Shock: High-density refractory materials are prone to spalling or cracking due to sudden temperature changes or significant temperature gradients between the hot and cold sides of the brick. In events like summer rainstorms, rapid cooling can cause damage to the refractory lining, leading to costly downtime for repairs. Even minor damage reduces the lining’s lifespan, adding to maintenance costs and production delays.

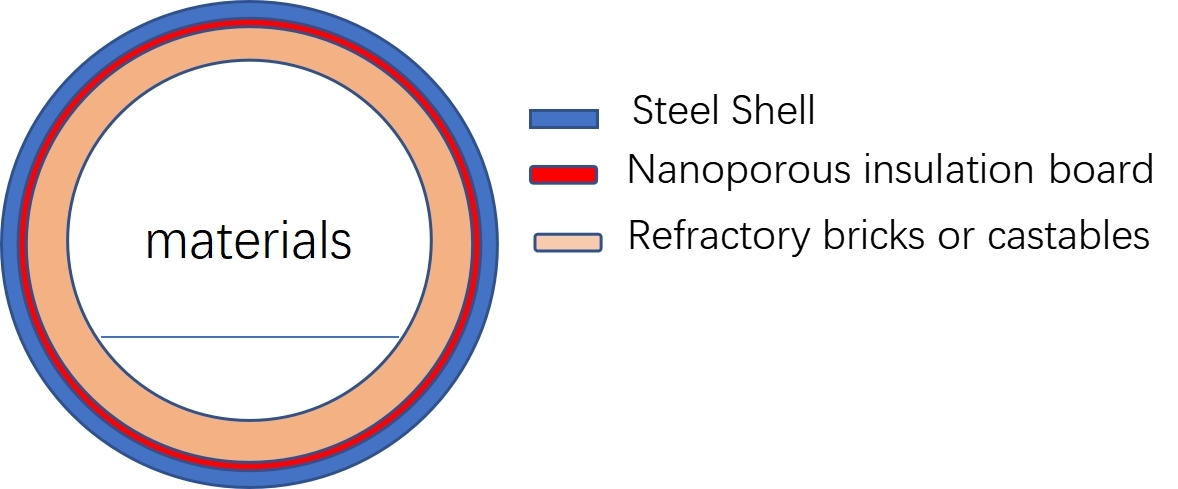

2. Insulating Between Refractory Materials and the Steel Shell

To address the high thermal conductivity and thermal shock tendencies of dense refractory materials, insulation is placed between the refractory and the kiln shell. Selecting the appropriate insulation involves considering several factors:

– Heat Resistance: The insulation must withstand the temperature behind the refractory, which varies by kiln zone and increases over time as the refractory wears down.

– Thermal Conductivity: Insulation with low thermal conductivity is crucial for reducing heat loss and energy consumption. The ideal insulation minimizes heat transfer via conduction, convection, and radiation, lowering the thermal gradient and reducing thermal shock.

– Mechanical Strength: The insulation must support the weight and movement of the refractory bricks. If the material is too soft, it may compress, lose its insulating properties, or cause brick displacement over time, compromising the entire lining.

– Thickness: While insulation reduces heat loss, adding too much increases the overall lining thickness and reduces the kiln’s internal diameter. Operators often use insulation bricks, but they are thick and have relatively high thermal conductivity, making installation labor-intensive.

The best insulation option is thin (1-3 cm), efficient, and easy to install. Some kilns use castable refractory materials, with insulation fixed using alloy anchors and covered with castable refractory. In such cases, the insulation thickness can be slightly increased. However, care must be taken to prevent microporous boards from direct water contact, which can be avoided by wrapping them in POF or aluminum foil.

3. Insulation Material Selection

The following insulation materials are commonly used in rotary kilns, with their respective pros and cons:

– Insulation Bricks: Require labor-intensive installation, are thick (≥6.5 cm), and have relatively high thermal conductivity.

– Ceramic Fiber Blanket: Thinner (6-12mm) and offers lower thermal conductivity than insulation bricks, but lacks density for mechanical wear resistance.

– Ceramic Fiber Paper: Thin with low thermal conductivity but contains binders that burn off, reducing mechanical strength.

– Microporous Board: The best choice, combining low thermal conductivity, high compressive strength, and excellent thermal stability, all encased in waterproof packaging.

4. Benefits of Using Microporous Board in Rotary Kilns

1. Lowest Thermal Conductivity: Microporous Board effectively minimizes all three modes of heat transfer (conduction, convection, and radiation), significantly reducing heat loss and energy consumption.

2. Reduced Heat Loss: It lowers the kiln shell temperature and reduces the heat absorbed by the mechanical drive system.

3. Decreased Thermal Gradient: Insulation behind refractory bricks reduces the thermal gradient, minimizing thermal shock and extending refractory lifespan.

4. Easy Installation: Microporous boards can be quickly installed with air-cured refractory mud or adhesive.

5. Thin Profile: Microporous boards are thin (3-15mm), allowing for efficient insulation without reducing the kiln’s internal diameter.

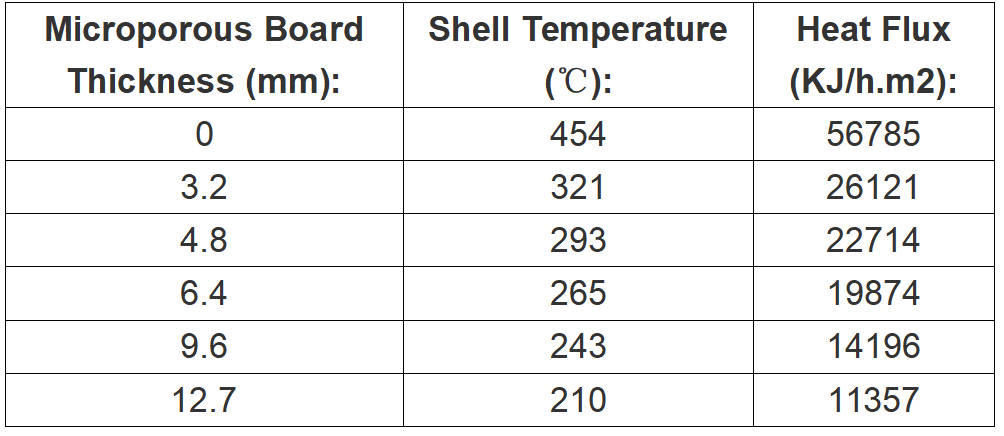

5. Case Study

In a scenario with a hot surface temperature of 1260°C and ambient temperature of 25°C, calculations performed using 15 cm thick high-alumina brick combined with microporous insulation boards (as per ASTM C-680 standards) showed that a microporous insulation layer just over 10mm thick reduced the kiln shell temperature by more than 200°C.

6. Conclusion

Using microporous boards between refractory materials and the kiln shell significantly reduces heat loss, extends the lifespan of the kiln and its mechanical systems, increases production capacity, and improves worker safety. Microporous boards have been widely adopted internationally, and expanding their use domestically offers a valuable opportunity for reducing energy consumption and operational costs, while aligning with the growing emphasis on energy efficiency and emissions reduction.

Stay Connected

For live updates and behind-the-scenes content, follow us on:

- LinkedIn: Firebird LinkedIn

- YouTube: Firebird YouTube

- Facebook: Firebird Facebook

- Website: Firebird main website