Under strict national eco policies and the trend of eliminating old capacities in casting, improving efficiency and achieving eco-friendly production have become priorities for many foundries. The combination of refractory materials with different types of insulation significantly impacts casting production outcomes and efficiency. Compared to traditional materials, the integration of nano-porous insulation boards with refractories has shown remarkable improvements in the lifespan, energy efficiency, safety, and productivity of iron ladles and tundishes. With their superior thermal insulation properties, nano-porous insulation boards are being widely adopted by foundries.

Challenges with Traditional Materials

Small-scale foundries typically use standard refractory materials, which have a shorter lifespan and require frequent repairs. These materials are prone to severe erosion and slag adhesion, especially in the upper section of the ladle, leading to an increase in diameter and compromising the purity of the molten iron. Medium and large-scale foundries often use plastic ramming mixes or castables, which offer a longer lifespan but still suffer from significant slag adhesion in the middle and upper sections of the ladle, affecting performance and iron purity.

Case Study: Iron Ladle Usage in Small and Medium-Sized Foundries

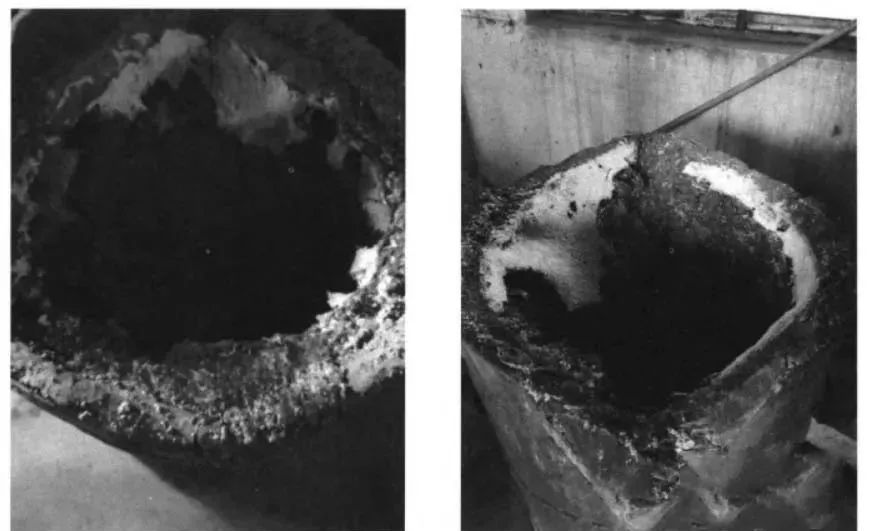

Gray Iron Ladles

The image above shows a ladle used for gray iron in small and medium-sized foundries. Typically, the ladle is used for about 100 pours, with a tapping temperature of 1460°C to 1480°C. During tapping, in-stream inoculation is performed. After tapping, slag coagulant is added, followed by stirring and slag removal. A second round of slag coagulant is evenly added, and the ladle is then lifted by an overhead crane to the pouring station. The slag at the ladle lip is pushed back using a slagging rod before pouring begins. After pouring, any residual slag is lightly tapped off with the slagging rod, and the ladle is ready for reuse.

Ductile Iron Ladles

The image below illustrates a ladle used for ductile iron in small and medium-sized foundries, employing the sandwich method for nodularization. The ladle is typically used for about 80 pours, with a tapping temperature of 1520°C to 1540°C. Before tapping, the ladle is cleaned of any adhered slag or iron residues. When the ladle temperature drops below 200°C, nodularizing agent is added to the bottom well, followed by 1/3 to 1/2 of the inoculant (some foundries add the entire amount at this stage). Additionally, 2-3 scoops of iron chips are added. Once the molten iron in the furnace meets the tapping requirements, tapping begins. Note: The side of the ladle containing the nodularizing agent should face the furnace to prevent direct impact from the molten iron. It is recommended to allow the molten iron to rise 20 cm above the dam before initiating the reaction. After the reaction subsides, tapping resumes. During tapping, the remaining inoculant is evenly added above the molten iron stream (some foundries place it in the tapping trough). After tapping, slag coagulant is added, followed by stirring and slag removal. This process is repeated a second time. Finally, after evenly adding slag coagulant again, the ladle is lifted by an overhead crane to the pouring station. The slag at the ladle lip is pushed back using a slagging rod before pouring begins. After pouring, the ladle is cleaned and prepared for reuse.

1. Application of Anti-Adhesion Slag Lining in Hot Metal Ladles

This product is characterized by its resistance to slag adhesion, non-reactivity with molten iron, strong corrosion resistance, and effective thermal insulation properties. It is easy to repair, offers excellent thermal shock resistance, extends service life, improves production efficiency, and reduces operational costs. Moreover, it effectively ensures the purity of molten iron, minimizing slag inclusion defects in castings.

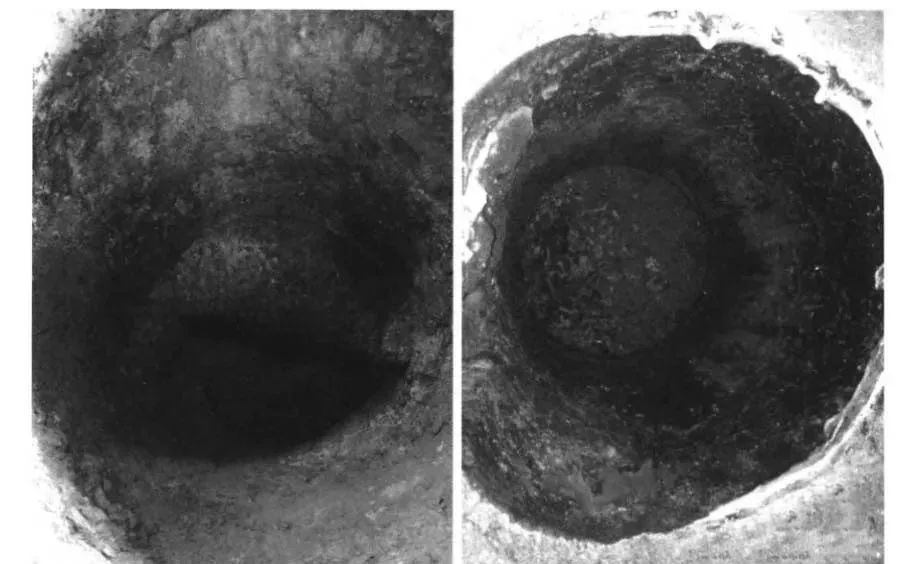

As shown in the image below, the inner surface of the ladle remains smooth with no irregularities, indicating that post-use cleaning is relatively easy.

2. Cost Analysis

1) Cost Analysis of Ladle Lining Materials

Using conventional ladle lining materials has a lower initial purchase cost. However, slag tends to adhere strongly to the inner walls, requiring extensive cleaning efforts. Frequent mechanical cleaning creates uneven surfaces, making subsequent slag adhesion even worse and reducing the ladle’s service life.

In contrast, anti-adhesion slag lining materials have a higher purchase cost but significantly reduce slag adhesion and are much easier to clean. This minimizes surface irregularities and extends the number of times a ladle can be used per lining by **3 to 4 times** compared to conventional linings.

2) Maintenance and Cleaning Labor Costs Per Use

The repair costs for conventional and anti-adhesion slag linings are similar. However, the cleaning costs for conventional linings are considerably higher. When cleaning conventional linings, only the top 1/3 to 1/4 of the inner surface can be effectively cleaned. As shown in Figures 1–4, slag residues remain in the middle and lower sections of the ladle, increasing the likelihood of slag inclusions in castings.

3) Analysis of Slag Inclusion and Incomplete Casting Defects

When molten iron enters the ladle, its temperature continuously decreases. Residual slag on the ladle’s inner walls, if not properly cleaned, gets reheated and begins to melt. Initially melted slag may be removed manually, but during ladle movement and pouring, additional molten slag can flow into the mold cavity along with the molten iron.

Filtration screens can only block solid slag, not liquid slag. When encountering a filter, liquid slag deforms and becomes finer. Although ceramic filters can partially capture liquid slag, they reduce the molten iron flow rate, prolonging the pouring time and increasing the risk of incomplete casting. Additionally, ceramic filters are significantly more expensive than resin filters.

4) Casting Price Analysis

Using chemically resistant anti-adhesion slag ladle lining materials reduces slag inclusion defects in castings. This results in a higher yield rate for castings that require gas-tightness tests. Furthermore, castings with airtightness requirements are priced significantly higher than standard castings.

Benefits of Nano Insulation Boards in Iron and Nodulizing Ladles

Improved Safety:

– Temperature Control: Nano insulation boards significantly reduce ladle shell temperatures, enhancing structural integrity and lifespan.

– Crack Prevention: Low shrinkage rates minimize the risk of cracks and gaps in the lining.

Enhanced Iron Quality:

– Stable Temperatures: Reduced heat loss allows for low superheat pouring, improving iron quality and reducing segregation, especially in ductile iron.

– Extended Holding Time: Facilitates better homogenization of composition and temperature, allowing impurities and gases to rise, resulting in cleaner iron.

Extended Refractory Life:

– Nano insulation boards reduce the temperature gradient across the refractory lining, extending its lifespan and reducing the frequency of replacements.

Energy Efficiency:

– Reduced Heat Loss: Lower heat loss minimizes the need for excessive superheating, saving energy and reducing refining costs.

– Preheating Savings: Improves ladle preheating efficiency, reducing online preheating time and energy consumption.

Increased Productivity:

– Capacity Expansion: Thinner insulation layers increase ladle capacity, preventing overflow and improving operational efficiency.

– Faster Production Cycles: Stable temperatures and smoother pouring processes accelerate production rhythms and boost output.

Product Features

Our nano insulation boards, developed through proprietary technology, offer exceptional high-temperature resistance, low thermal conductivity, fire resistance, lightweight properties, and environmental friendliness. They are indispensable for industries such as metallurgy, chemicals, defense, and aerospace.

Installation and Usage

Nano insulation boards are easy to install, either with adhesive or anchors, and can be cut to size for custom applications. They are placed as the innermost layer of the ladle lining, followed by castables, repair materials, and anti-slag coatings. It is important to note that nano insulation boards should not come into direct contact with molten iron, as their primary function is thermal insulation.

The use of nano thermal insulation materials is becoming increasingly prominent in industries such as petrochemicals, machinery, and construction. With future advancements, nano insulation materials are expected to gradually replace traditional insulation materials.

Conclusion

Nano insulation boards represent a significant advancement in ladle insulation technology, outperforming traditional materials like ceramic fiber by 3-4 times. With their superior performance, ease of installation, and long-term cost benefits, they are poised to become the standard in the foundry industry.

Stay Connected

For live updates and behind-the-scenes content, follow us on:

- LinkedIn: Firebird LinkedIn

- YouTube: Firebird YouTube

- Facebook: Firebird Facebook

- Website: Firebird main website